The window hole can become one of the main thermal bridges inside a house, for this reason its insulation is fundamental to ensure a high degree of living-comfort. The window system is usually made up of the window, frame and eventually the box for the roller shutter. To eliminate heat loss, each of these elements must be correctly insulated.

The insulation of the windows is often guaranteed by the double glass, which thanks to the air cushion between the two layers, counteracts the passage of heat. To complete the insulation of the window hole the most efficient and practical solution for installation is the insulating monoblock. It is custom-made and includes inside all the insulating elements to interrupt the thermal bridge through the window hole.

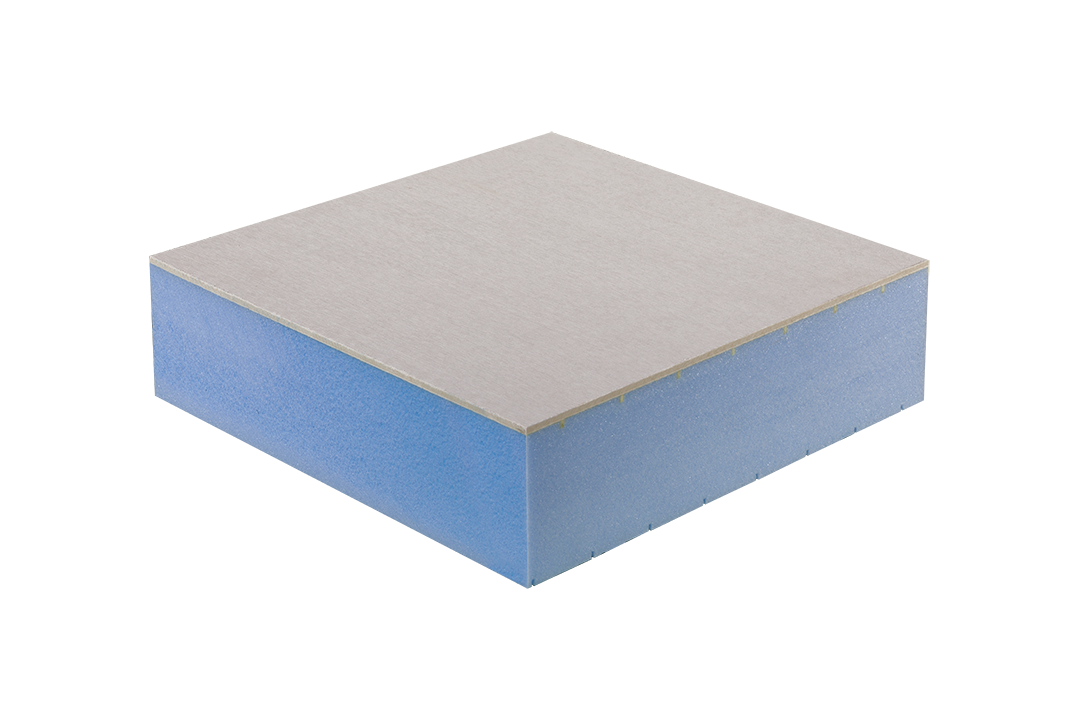

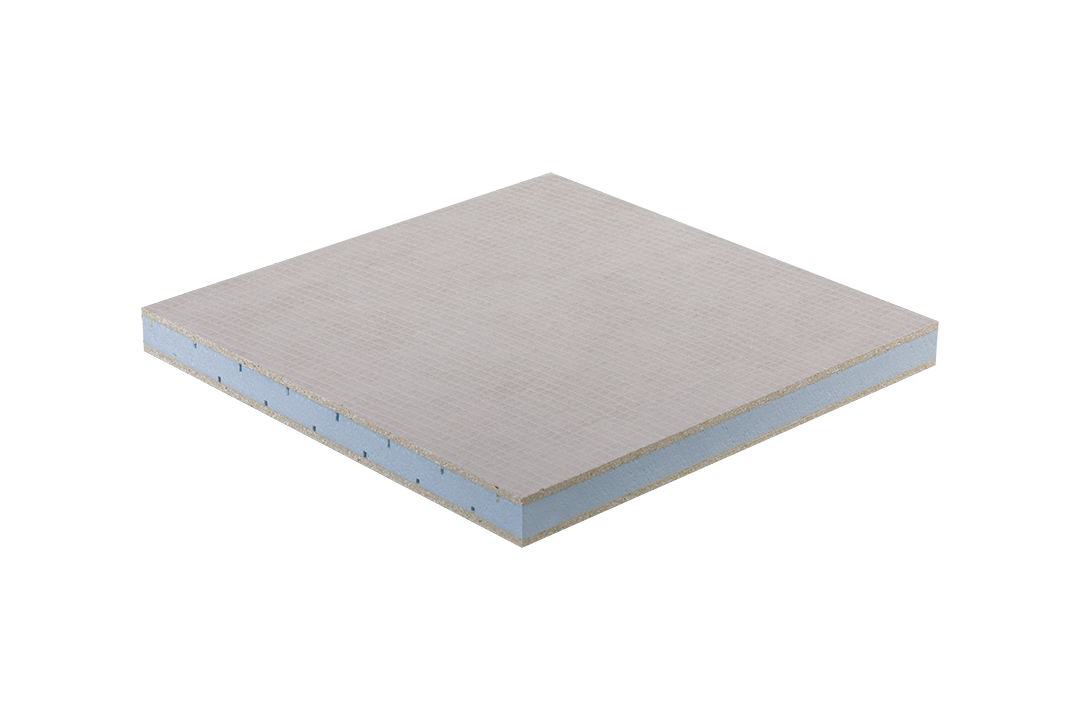

The insulation of the closing panels is obtained through the use of Corevo Block thermal insulation panels. The boards in XPS are coupled with fiber-cement or magnesium oxide on one or both sides. The XPS performs the function of insulating, and unlike other similar materials it is able to resist humidity and thanks to its high mechanical properties, resists to the stress that can occur during installation and the mechanical stresses that occur during the life of the window. The support, on the other hand, functions as a vapour barrier and guarantees high rigidity to the whole structure. The insertion of these thermal insulating elements inside the system makes the monoblock, the best solution for the insulation of windows.

The products designed specifically for these needs are: Corevo Foam, Corevo H, Corevo Block FC and Corevo Block MGO.