When you buy a front door or an industrial door there are many aspects to take into consideration. Aesthetics, safety and durability are certainly some of the main, but equally important are also all the characteristics of thermal insulation and living-comfort. A properly insulated door simultaneously acts as a barrier against the atmospheric agents, protection against mold and condensate, also obstructs the passage of heat. Oppositely, if not well insulated, it can become a zone of reduction of the thermal resistance of the building, which constitutes a preferential point for the passage of heat.

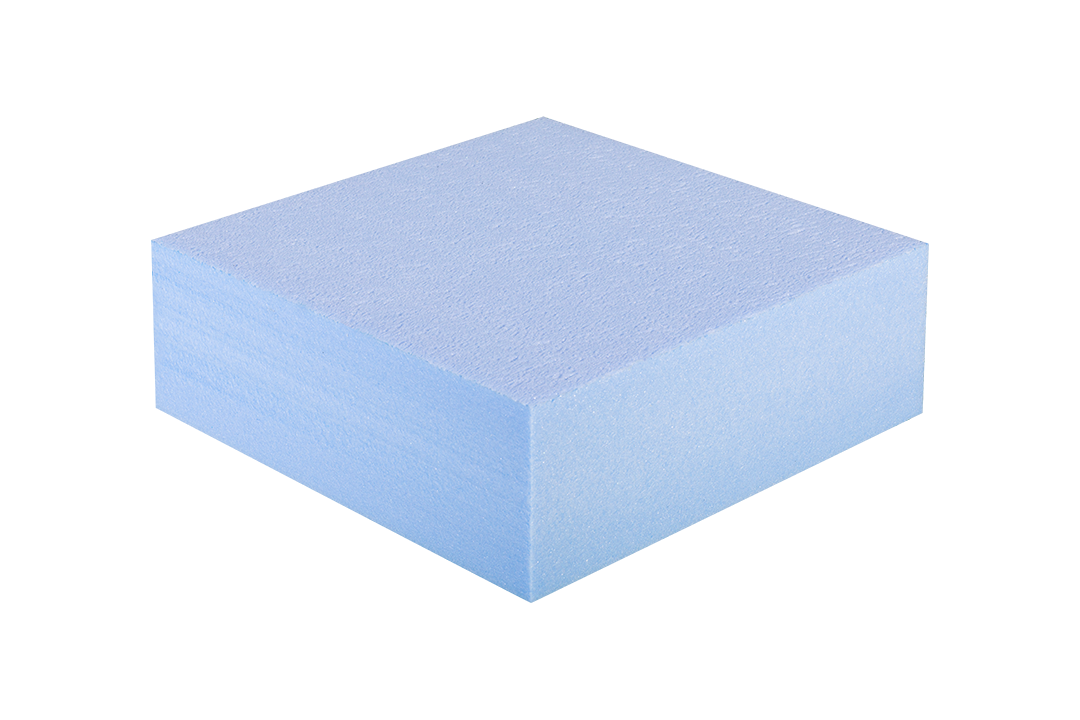

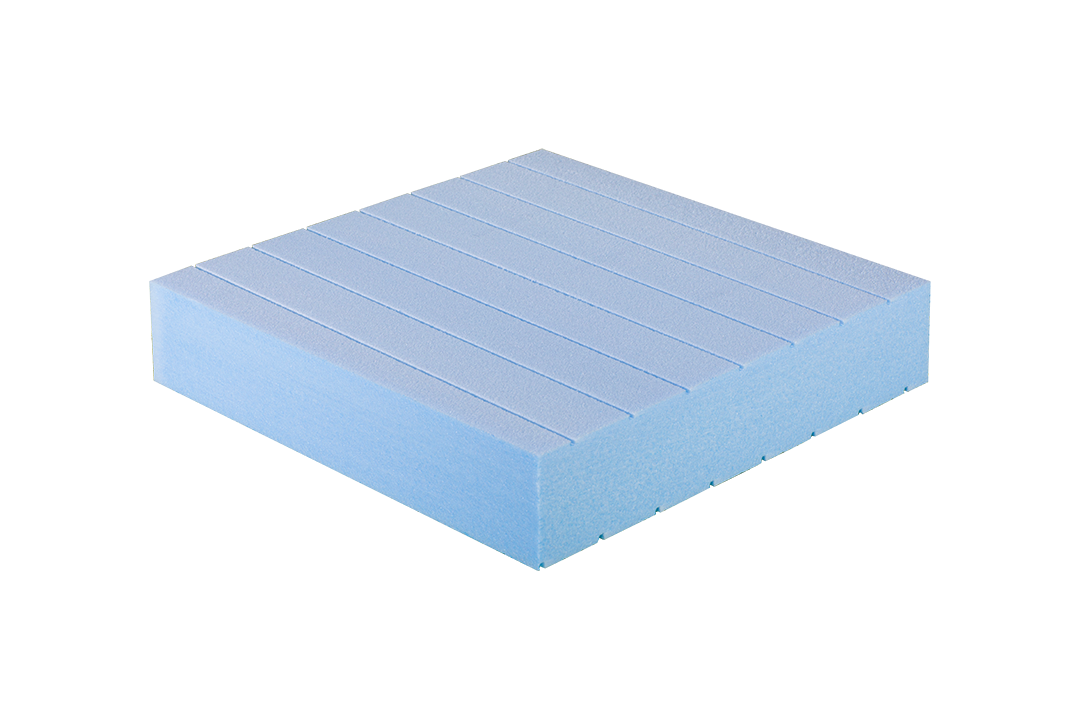

The Corevo extruded polystyrene boards XPS inserted inside the doors, ensure optimal thermal insulation thanks to the reduced thermal conductivity of the material. In addition, the microstructure of extruded expanded polystyrene with closed cell, ensures a very reduced water and steam absorption, high dimensional stability and preservation of insulating properties throughout the door’s lifetime. The XPS also distinguishes itself from other insulating materials, for its high mechanical properties, which make the doors solid and resistant to any type of stress. The surface of the panel is rough and suitable for bonding; while the presence of longitudinal grooves on the surface, available on request, prevent the formation of air bubbles between the insulation and the supports on which it is applied. The wide range of panels and the possibility to customize the format makes Corevo the ideal solution for all types of doors and a perfect response to environmental and energy saving challenges.

The products designed specifically for these needs are: Corevo Foam and Corevo H.

-9FeP.jpg)